New Handling Center (NPC)

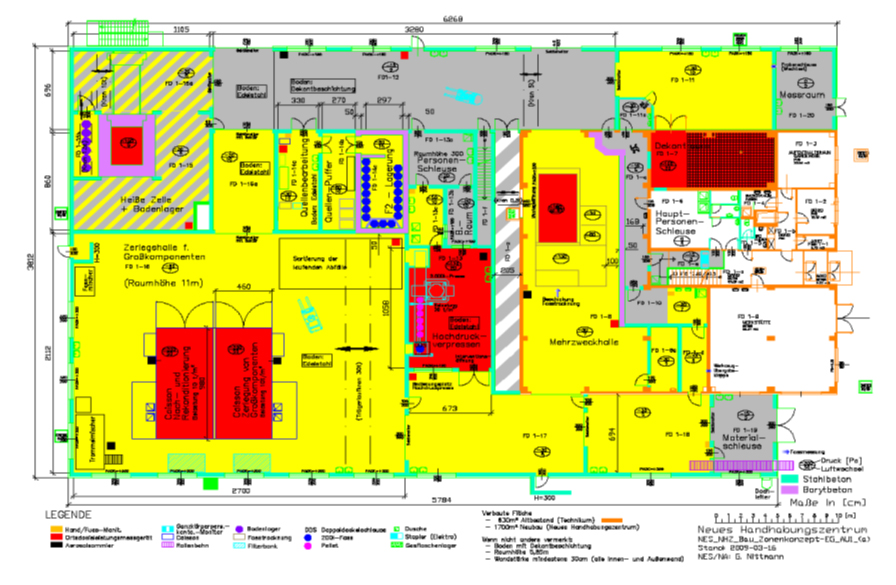

The NHC was built in the years 2010-2013. During planning and execution, the main focus was on optimising material and personnel traffic, occupational safety and radiation protection. For example, we made sure to deploy the clearest and most unambiguous flow of materials (‘one-way system’), and we implemented extensive structural measures (e.g. airlock systems) and building installations (e.g. ventilation systems) to minimise the risk of radioactive material release as much as possible. The following figure shows the floor plan of the ground floor of the NHC. Technical equipment and supplies, in particular the ventilation system, are on the 1st floor.

Floor plan of the New Processing Centre

The building is divided into four zones (white/grey/yellow/red) based on ascending risk of contamination:

In the white zone there is no handling of radioactive substances; this area contains, for example, changing areas and sanitary facilities. The contamination risk is very low here.

The grey zone is formed by air lock areas in which radioactive substances are only handled in closed containers. The risk of contamination is low here.

In the yellow zone, work is being performed with radioactive substances. Thus, contamination cannot be completely ruled out (average risk of contamination).

The red zone is formed by areas that are intended and equipped for handling radioactive substances. Accordingly, release of contaminants should be expected.

All zone borders and transitions feature appropriate air locks, where staff members change clothing or apply protective equipment before they enter areas with higher risk of contamination, and where they undergo radiological control measurements before leaving.

The NHC is equipped with a ventilation system that generates strong air exchange and negative pressure throughout the building in order to minimise the risk of radioactive substances being released into the environment as much as possible. Inside the building, the negative pressure is staggered, so that directional air flow is always ensured from areas with a lower risk of contamination to those with a higher risk; this means that the highest negative pressure is maintained in the red zones. The exhaust air from the building is filtered accordingly and monitored for radiology.

In addition to the exhaust air, the entire building is also closely monitored for radiology (e.g. dose rate measurements, measurement of ambient air activity, contamination monitors, etc.).

The NHC comprises numerous facilities for the processing and conditioning of radioactive waste. The main facilities are:

Glimpse at the hot cell

Hot cell with undergroud storage for the treatment of High-activity Sealed Radioactive Sources. Since the radiation emitted by the HASS sources is so strong, they can only be handled in the hot cell, which consists of 1 m thick heavy concrete, with manipulators from the outside. A underground storage for temporary storage of the sources is located below the cell.

Source processing centre: This is where the equipment for treatment of enclosed radioactive substances (radiation sources) is located.

2 stainless steel caissons: These are essentially large processing chambers in which radioactive waste can be decomposed, crushed, decontaminated and prepared for further conditioning by personnel in force-ventilated protective suits. Since these activities involve the release of radioactive substances into the ambient air, the caissons are equipped accordingly (ease of decontamination, strong air exchange, high negative pressure and directional air flow, elaborate filtering of exhaust air, etc.). The caissons are designed to be multifunctional, facilitating a variety of procedures for breakdown, crushing, decontaminating, and processing radioactive waste.

High-pressure compactor with handling system

High-pressure compactor: The fully enclosed and remotely operated high-pressure compactor with the required automatic handling system is used for compressing non-combustible radioactive waste.

A look inside the 32-drum drying chamber

Drum drying facility: Drums are dried in the 32-drum drying chamber prior to being sealed and transferred to the interim storage to minimize the risk of chemical processes and corrosion in the barrel. This facility is essentially a large drying cabinet in which up to 32 pieces of 200L drums are dried simultaneously at a temperature of about 120 °C for about 1 week.

Decontamination room: Contaminated objects and materials, empty drums, and similar, can easily be cleaned and decontaminated here with high pressure water jets.